Why Making Suppliers Register for Every Project Is Slowing Industry Down

Across Australia, governments and major projects are working hard to improve supplier engagement, strengthen local industry capability, and streamline procurement. Yet despite these ambitions, an outdated sourcing practice persists in the industry, a manual supplier registration process that requires suppliers to re-register for every single project.

Organisations are actually out proudly championing this as if it were a huge benefit, claiming that even if a supplier is already registered on the tendering platform, they must still find each new project page and sign up again to be considered. Hooray, more work for you!

This kind of manual supplier registration model does the opposite of streamlining procurement, and at BenchOn, we fundamentally disagree with this approach.

This practice creates a “hope and wait” sourcing model: the buyer posts an opportunity, then sits back hoping the right suppliers will not only hear about it, but take the time to find it and manually register. This is not strategic sourcing. It is a gamble, and it is the root cause of many of the supply chain failures we see across major industries today. If you want the bigger picture behind moving beyond “hope and wait”, read our article on early market engagement, Part 1 of our 4-part series on the key supply chain issues to fix in 2026.

Below, we break down the structural issues created by forcing suppliers to re-register for every project, and show how a proactive, capability-based matching approach, like BenchOn’s, solves them.

1. Procurement timelines blow out because buyers must wait for suppliers to find them

Forcing suppliers to manually register for each project through the same supplier registration process automatically introduces delays. Because the buyer cannot know when suppliers will discover the project page, if they find it at all, they must leave registrations open for extended periods.

This “wait for responses” phase slows everything down and creates procurement delays:

- Project teams delay evaluation while waiting for more registrations,

- Procurement readiness is pushed out, and

- Internal stakeholders lose visibility and momentum.

When time is mission-critical, a sourcing model built on “wait and see” is no longer fit for purpose.

2. Buyers only see a slice of the supply chain, not the full market

A project webpage on a tendering platform does not equal supplier visibility. It only captures:

- Suppliers who happen to see the announcement,

- Suppliers with available time to submit,

- Suppliers who understand the platform, and

- Suppliers who are not overwhelmed by the volume of irrelevant tenders they already monitor.

This inevitably leads to partial, skewed market engagement. Under this supplier registration process, the most capable suppliers for the work might never even know the opportunity existed. Meanwhile, buyers assume they are performing “market engagement” simply because a project page is live.

This is how major projects end up saying, “We could not find the right suppliers.” They were there. The system just never reached them or provided true supply chain visibility.

3. Sourcing organisations lose their supply chain after every project

One of the most harmful side effects of project-based supplier registration systems is the reset button it presses on the supply chain. After each project closes:

- The project page disappears,

- The supplier registrations vanish, and

- The sourcing company is left with only a narrow list of those who responded last time.

When the next project begins, the entire supplier registration process starts from scratch.

This approach makes it impossible to build:

- A reliable supplier database,

- A repeatable engagement strategy,

- Long-term industry capability, and

- A resilient supply ecosystem that grows over time.

Every new project becomes ground zero again, wasting time and losing institutional knowledge.

4. Suppliers waste enormous time trying to track opportunities across dozens of platforms

Small and medium enterprises (SMEs) are the backbone of local industry. Yet they are often the most stretched for time and resources. Many SMEs are registered across 15 or more different tendering platforms and websites, each with its own login, notification system, and project page format.

This creates serious challenges for the suppliers, including:

- Administrative overload,

- Notification fatigue,

- A flood of irrelevant opportunities they must sift through, and

- Difficulty identifying which opportunities are actually suitable.

When suppliers have to constantly hunt for project pages and repeat the same supplier registration process across platforms, the system is broken. The burden of sourcing has shifted onto suppliers, when it should rest with the buyer and the platform.

5. The best suppliers are often too busy to monitor every announcement

Ironically, the most capable, in-demand and high-quality suppliers are the ones most likely to miss manually posted opportunities.

Why? Because they are already working!

A sourcing system that relies on constant monitoring of project pages and a manual supplier registration model penalises the very suppliers buyers want most.

This means:

- High-performing suppliers miss relevant projects,

- Buyers unknowingly exclude the strongest talent, and

- The quality of responses drops.

This is not just inefficient. It directly undermines project outcomes.

6. Suppliers rarely receive feedback or transparency

In many project-based supplier registration systems, once suppliers submit their expression of interest, they hear nothing further – no updates, no feedback, and no indication of whether they were shortlisted.

This creates mistrust in the system and discourages future participation.

A modern sourcing ecosystem and supplier registration process should be built on transparency and engagement, not silence.

Why this approach fails industry

When you combine all of these issues, you see the larger systemic problem:

Manual, project-based supplier registration is not a market engagement strategy. It is a bottleneck in your supplier registration process.

It leads to:

- Fragmented supplier data,

- Incomplete market visibility and poor supply chain visibility,

- Inefficient procurement processes,

- Reduced competition and innovation,

- Wasted supplier effort,

- Missed local capability, and

- Slower project delivery.

This is not how modern supply chains should operate. Even the Queensland Procurement Policy 2026 highlights that simplifying access to procurement opportunities strengthens market diversity and encourages more suppliers to participate, rather than putting extra barriers in their way.

How BenchOn solves these problems

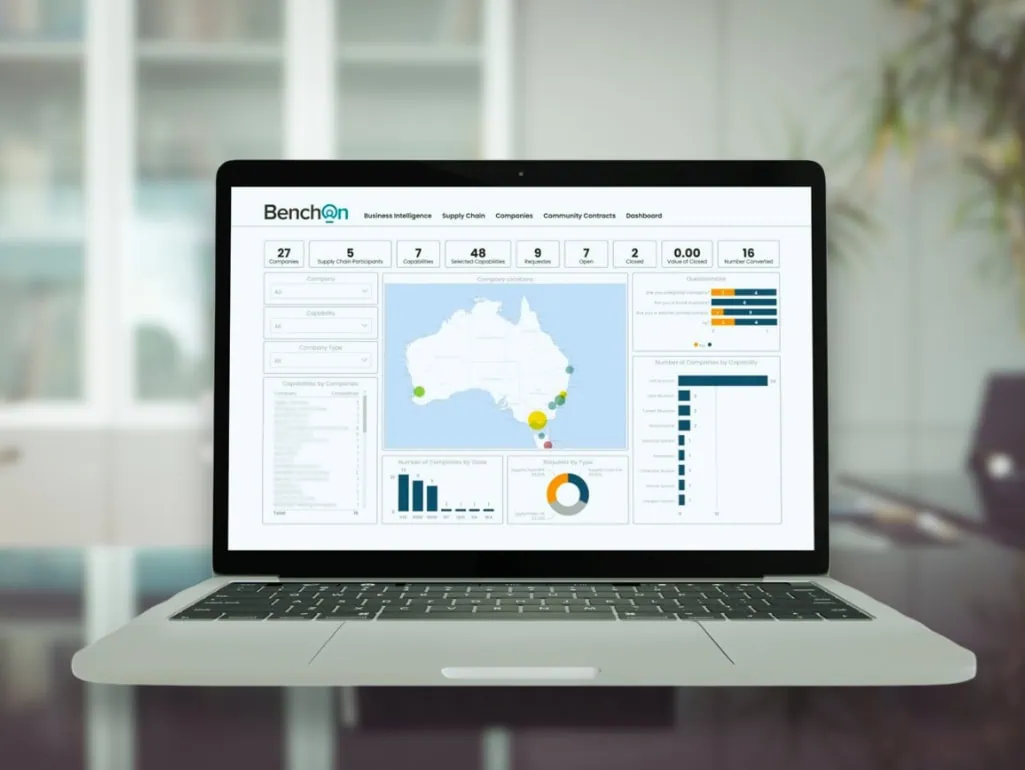

BenchOn was built to address these exact shortcomings and to create a sourcing model and supplier registration process that genuinely connect buyers with the full depth of local industry capability. For enterprise and government buyers, BenchOn enterprise solutions and BenchOn government solutions turn fragmented supplier data into a persistent supplier database and improve supply chain visibility, so every project builds on what you already know instead of starting from scratch.

To see how this works in practice, watch the short BenchOn enterprise solutions overview below.

Here is how we do it differently:

1. Suppliers register once, only once

With BenchOn, suppliers only need to create their profile once. Their capabilities, skills, products, and services are stored centrally, transferred into all joined portals, and updated as needed.

- No repeated registrations,

- No hunting for project pages, and

- No administrative burden.

2. BenchOn proactively notifies every suitable supplier

Instead of expecting suppliers to find opportunities, BenchOn reverses the model with proactive, capability-based matching and AI supplier matching.

When a buyer posts a requirement, BenchOn automatically matches the opportunity against the capability profiles of every registered supplier. Then, BenchOn notifies the relevant suppliers directly.

This ensures:

- No capable supplier is ever missed,

- High-quality, busy suppliers are still engaged,

- Local suppliers are always considered, and

- Buyers receive a complete, accurate market picture.

It is proactive sourcing, not passive posting.

3. Buyers build a true, growing Supply Chain

Because supply-chain data is persistent in a central supplier database, buyers accumulate insights over time on their supplier capability data:

- Which suppliers engaged,

- Their capabilities,

- Their responsiveness, and

- How they performed.

Each project strengthens the organisation’s supply network and improves supply chain visibility, instead of resetting it.

4. Transparency and feedback are built in

BenchOn provides structured communication throughout the supplier registration process so suppliers understand:

- Whether they matched,

- Whether they were shortlisted,

- Why they were unsuccessful, and

- What next steps look like.

This builds trust, encourages participation, and supports long-term industry development.

5. Everyone saves time, effort, and money

By automating capability matching and supplier notifications in the supplier registration process:

- Procurement teams spend less time searching and waiting, and streamline their procurement processes,

- Suppliers spend less time monitoring dozens of platforms,

- Projects achieve readiness faster,

- Engagement costs are dramatically reduced, and

- Local businesses gain more opportunities.

It is a win for buyers, suppliers, and the broader economy.

Conclusion: It is time to move beyond “hope and wait”

The practice of making suppliers re-register for every project through a manual supplier registration process is a relic of a past era. It creates avoidable delays, fragments supply chains, burdens small businesses, and results in incomplete engagement that harms project outcomes.

BenchOn’s proactive, capability-driven model solves these issues, using capability-based matching to ensure that every supplier who can deliver on a requirement is automatically notified, while buyers gain immediate access to the full breadth of local capability. If you want the bigger picture behind this approach, including how connected capability works as a scalable network model, read our article “Industry Matching System: Unlocking the Full Power of Industry Through Connected Capability“.

If you are a supplier, BenchOn supplier solutions make it easier to register once, be matched to the right opportunities and spend less time chasing dozens of tendering platforms.The result is a faster, smarter, fairer sourcing ecosystem that benefits everyone.

If you are ready to move beyond hope and wait in your own supplier registration process, get in touch with the BenchOn team to explore what this could look like for your organisation.