Industry Matching System: Unlocking the Full Power of Industry Through Connected Capability

Why an industry matching system matters now

At BenchOn, we believe the next era of economic growth will not be driven by scale alone, but by connection. For decades, industries have been organised in silos, individual businesses optimising internally, yet under-utilising the vast strength that exists around them. Today, that model no longer serves the pace or complexity of modern markets. The future belongs to connected capability, a model where industry value is created through structured, intelligent connection.

An industry matching system turns connection into a repeatable mechanism, so capability can be found, validated, and activated without relying on personal networks alone. It effectively functions as a capability matching system for modern industry.

From static supply chains to connected capability

Connected capability recognises that every business, regardless of size, holds unique strengths, skills, assets, capacity, and expertise, that extend far beyond its own four walls. When these strengths are visible and linkable across an industry, they form a living system rather than a static supply chain. Value no longer moves in a straight line, it flows dynamically, adapting in real time to opportunity, demand, and innovation.

For this to work at scale, the underlying data needs structure. That is where a capability discovery system supported by a supplier capability database becomes essential, because it keeps capability signals consistent and searchable over time.

A network model that avoids bottlenecks

At the centre of this model is an endless hub-and-spoke connection. Each business operates as its own hub, connected into a broader industry network, while simultaneously acting as a spoke to others. There is no single point of control and no central bottleneck. Instead, connection is continuous, resilient, and infinitely scalable. New participants can join at any time, immediately accessing industry capability while contributing their own. The industry begins to function as a coordinated whole, without sacrificing independence, competition, or identity. This is what makes buyer supplier matching practical, because matching is distributed across the network rather than funnelled through a single gate.

The economic benefits of connected capability are significant and compounding. When industry capability matching is enabled through a supplier matching system, that compounding effect accelerates because matching improves with each cycle of engagement and data refresh.

Where connected capability creates compounding value

First, it dramatically increases utilisation. Across every sector, there is underused capacity, idle equipment, surplus workforce availability, specialist expertise, and untapped innovation. By making these capabilities discoverable and accessible, inefficiency converts into productivity. This is where a capability discovery system matters, it helps buyers see what exists before they default to the same suppliers. Suppliers generate greater returns from existing assets, while buyers gain faster, more flexible access to solutions. This growth can occur without proportional increases in capital expenditure.

Second, it reduces friction and transaction costs. Traditional procurement and partnership models are slow, opaque, and resource-heavy. A connected industry enables rapid matching of need to capability, reducing time-to-market and administrative overhead. This is the practical outcome of buyer supplier matching, supported by a supplier matching system that can filter, compare, and shortlist. As this efficiency compounds across the network, costs fall, margins improve, and economic value is created at scale. A supplier shortlisting system strengthens this step by producing clear, decision-ready shortlists from structured capability signals. It also supports project supplier matching when teams need to repeat the same shortlisting logic across multiple work packages or regions.

Third, connected capability delivers not just resilience, but anti-fragility. In a fragmented industry, shocks expose weakness. In a connected one, disruption becomes a source of strength. Australia’s Productivity Commission has noted that supply chain disruptions can be costly and detrimental to the well-being of Australians. When demand shifts, supply chains fracture, or workforce availability changes, the network can rebalance dynamically, redirecting work, sharing capacity, and reallocating expertise. For a practical example of how regulation can change supplier engagement and workforce models, read our article South Australia labour hire licensing changes.

Each disruption strengthens the system by improving its ability to adapt. This creates industries that do not merely survive volatility, but learn from it and emerge stronger. A supplier discovery tool supports supply chain supplier discovery by surfacing credible alternatives early, before gaps become failures. To learn more about ‘anti-fragility’ read this article (https://onlinelibrary.wiley.com/doi/full/10.1111/jscm.12313) or speak to Amanda MacKinnell (https://www.linkedin.com/in/amanda-mackinnell-mba-maipm-49364391/) from L3 Harris who is working on the concept for her PHD.

Fourth, connected capability accelerates innovation. When businesses are visible to one another, collaboration becomes frictionless. Ideas move faster, cross-sector partnerships emerge organically, and innovation is no longer confined to the largest players. Small and medium businesses gain access to opportunities previously beyond reach, while larger organisations benefit from a deeper pool of specialised expertise and capability.

Finally, this model drives inclusive and sustainable growth. Participation is no longer limited by scale or proximity. Economic opportunity is distributed more evenly across the industry, strengthening regional economies, supporting employment continuity, and creating a more balanced growth ecosystem. The simplest way to widen participation is to make supplier shortlisting more transparent through capability-based sourcing, so suppliers are found on fit, not familiarity.

BenchOn’s mission for connected capability

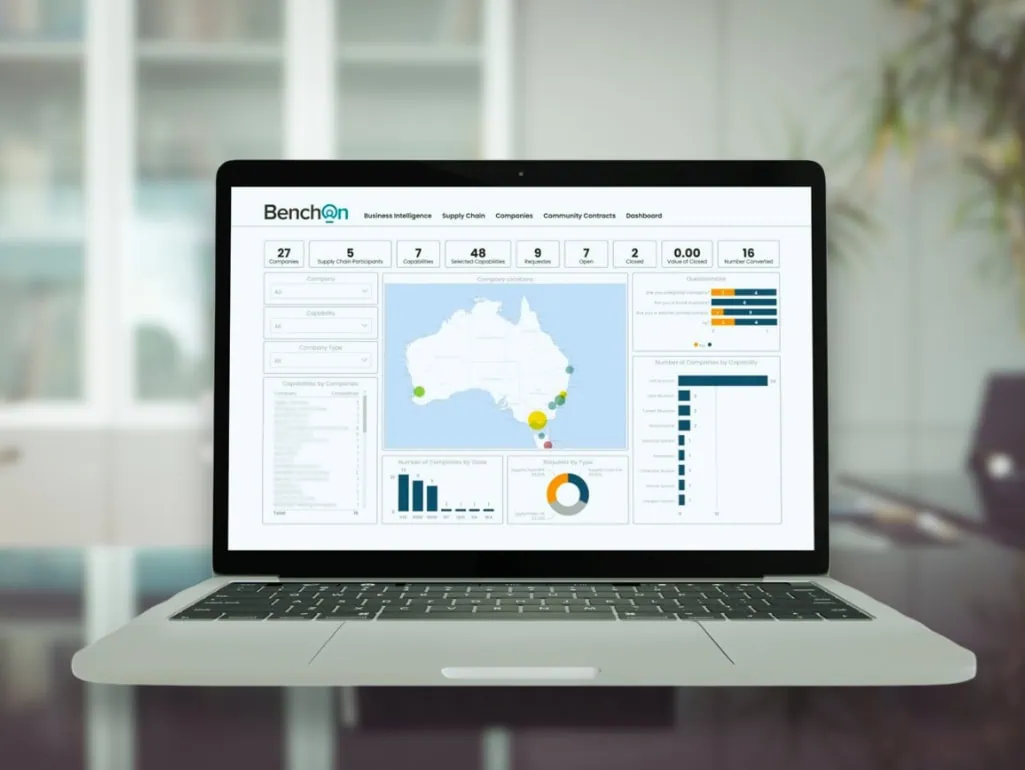

At BenchOn, our mission is to make connected capability the foundation of modern industry. When every business is linked through an endless hub-and-spoke of opportunity, we do not just improve efficiency, we unlock the full power of industry itself.

If you want to see what this looks like in practice, explore how BenchOn works, or get in touch to discuss your industry goals and what an industry matching system could look like in your environment.

FAQs

How does an industry matching system work in practice?

An industry matching system maps out supplier capability and expertise across a number of data points like location, industries supported, accreditations and quality systems and then intelligently matches those suppliers to requests from buyers so that suppliers are notified directly that an opportunity suits their business. This produces valid responses to the buyer faster than manual referrals, emails or searching spreadsheets.

What information do suppliers need to provide to be matched accurately?

To get accurate matching, suppliers should provide a capability profile that is specific and current. The most important things to provide are the key capabilities that the business can deliver as well as the skill sets resident in the company. Regularly update your skill sets and capabilities as they evolve and change for the most accurate matching to opportunities. Company profiles can be updated quickly and easily through the dashboard. The goal is simple, a buyer should be able to understand fit without chasing emails.

Is a buyer-supplier matching system only useful for major projects?

No. A buyer-supplier matching system can be valuable for any organisation that needs to find fit-for-purpose suppliers quickly. It becomes more important as the supplier base grows, projects become more specialised, or engagement moves beyond personal networks.

What makes a supplier discovery tool better than manual procurement processes?

A supplier discovery tool reduces time spent searching, emailing, and validating basics. It improves consistency in how suppliers are found and compared, and it helps uncover relevant suppliers that are not already known to the project team, which is often where value is lost.

What is the first step to implementing capability-based sourcing using an industry capability matching approach?

Start by breaking down the capabilities that your business will need for your projects or business operations. This becomes your specific capability taxonomy that suppliers will align with when registering in your portal. If you get the structure right early, capability-based sourcing becomes repeatable and scalable, instead of being rebuilt for every project.